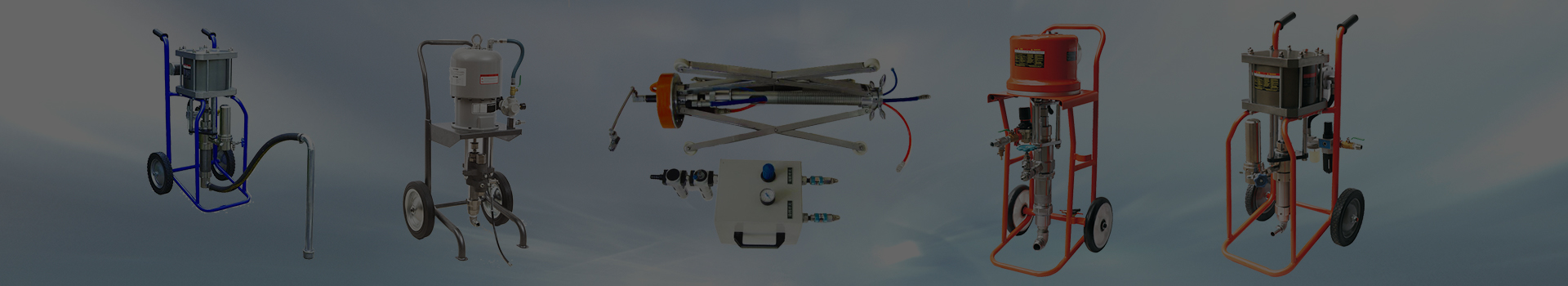

Airless Spraying Equipment

Equipment composition

Airless spraying equipment is generally composed of power source, high-pressure pump, pressure storage filter, paint delivery high-pressure hose, paint container, spray gun, etc. (see Figure 2).

(1) Power source: The power source of high-pressure pump for coating pressurization includes compressed air drive, electric drive and diesel engine drive, which are generally driven by compressed air, and the operation is simple and safe. Shipyards are driven by compressed air. The devices using compressed air as power source include air compressor (or air storage tank), compressed air transmission pipeline, valve, oil-water separator, etc.

(2) Spray gun: airless spray gun consists of gun body, nozzle, filter, trigger, gasket, connector, etc. The airless spray gun only has a coating channel and no compressed air channel. The coating channel is required to have excellent sealing property and high pressure resistance, without leakage of high-pressure coating after pressurization. The gun body should be light, the trigger should be easy to open and close, and the operation should be flexible. Airless spray guns include hand-held spray guns, long rod spray guns, automatic spray guns and other types. The hand-held spray gun is light in structure and easy to operate. It can be used for various airless spraying operations in fixed and unfixed occasions. Its structure is shown in Figure 3. The long rod spray gun has a length of 0.5m – 2m. The front end of the spray gun is equipped with a rotary machine, which can rotate 90 °. It is suitable for spraying large workpieces. The opening and closing of the automatic spray gun is controlled by the air cylinder at the end of the spray gun, and the movement of the spray gun is automatically controlled by the special mechanism of the automatic line, which is applicable to the automatic spraying of the automatic coating line.

(3) High pressure pump: High pressure pump is divided into double acting type and single acting type according to the working principle. According to the power source, it can be divided into three types: pneumatic, hydraulic and electric. Pneumatic high-pressure pump is the most widely used. The pneumatic high-pressure pump is powered by compressed air. The air pressure is generally 0.4MPa-0.6MPa. The pressure of the compressed air is regulated by the pressure reducing valve to control the paint pressure. The paint pressure can reach dozens of times of the compressed air input pressure. The pressure ratios are 16:1, 23:1, 32:1, 45:1, 56:1, 65:1, etc., which are applicable to coatings of different varieties and viscosity.

Pneumatic high-pressure pump is characterized by safety, simple structure and easy operation. Its disadvantages are large air consumption and high noise. The oil pressure high-pressure pump is powered by oil pressure. The oil pressure reaches 5MPa. The pressure reducing valve is used to regulate the spraying pressure. The oil pressure high-pressure pump is characterized by low power consumption, low noise, and safe use, but it requires a dedicated oil pressure source. The electric high-pressure pump is directly driven by alternating current, which is convenient to move. It is most suitable for unfixed spraying places, with low cost and low noise.

(4) Pressure storage filter: generally, pressure storage and filtering mechanism are combined into one, which is called pressure storage filter. The pressure storage filter is composed of cylinder, filter screen, grid, drain valve, paint outlet valve, etc. Its function is to stabilize the coating pressure and prevent the instantaneous interruption of coating output when the plunger of the high-pressure pump reciprocates to the conversion point. Another function of the pressure storage filter is to filter impurities in the coating to avoid nozzle blockage.

(5) Paint transmission pipeline: the paint transmission pipeline is the paint channel between the high-pressure pump and the spray gun, which must be resistant to high pressure and paint erosion. The compressive strength is generally 12MPa-25MPa, and it should also have the function of eliminating static electricity. The structure of paint transmission pipeline is divided into three layers, the inner layer is nylon tube blank, the middle layer is stainless steel wire or chemical fiber woven mesh, and the outer layer is nylon, polyurethane or polyethylene. The grounding conductor must also be wired for grounding during spraying

Post time: Dec-02-2022