Equipment selection principle

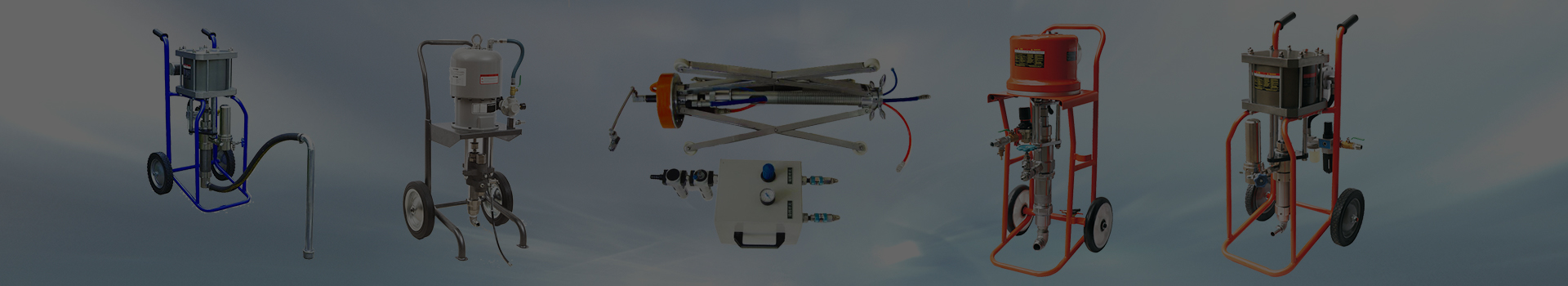

There are many types of airless spraying equipment, which shall be selected according to the following three factors.

(1) Selection according to coating characteristics: first of all, consider the viscosity of the coating, and select equipment with high pressure ratio or heating system for coatings with high viscosity and difficult atomization. Special equipment with special model shall be selected for two-component coating, water-based coating, zinc rich coating and other special coatings.

(2) Select according to the condition of the coated workpiece and the production batch: this is the main factor for selecting equipment. For the small or small batch of coated workpieces, generally select the model with small paint spraying amount. For the large and large batch of workpieces, such as ships, bridges, automobiles, continuous automatic lines for painting, select the model with large paint spraying amount. Generally, paint spraying volume<2L/min is small, 2L/min – 10L/min is medium, and>10L/min is large.

(3)According to the power source available, pneumatic airless spraying equipment can be selected because there are compressed air sources in general spraying workplaces. If there is no compressed air source but only power supply, electric airless spraying equipment shall be selected. If there is neither air source nor power supply, engine driven airless spraying equipment can be selected

Advantages of high-pressure airless spraying machine:

1. High spraying efficiency. The spray gun sprays paint completely. The spray flow is large, and the construction efficiency is about 3 times that of air. Each gun can spray 3.5~5.5 ㎡/min. The ultra-high pressure airless spraying machine can operate up to 12 spray guns at the same time. The maximum nozzle diameter can reach 2mm, which is suitable for various thick paste coatings.

2. Little rebound of paint. The paint sprayed by the air spraying machine contains compressed air, so it will rebound when touching the surface of the object to be coated, and the paint fog will fly away. The paint fog sprayed by high-pressure airless spraying has no rebound phenomenon because there is no compressed air, which reduces the spray hair caused by the paint fog flying, and improves the utilization rate of the paint and the quality of the paint film.

3. It can be sprayed with high and low viscosity paint. As the transportation and spraying of coatings are carried out under high pressure, high viscosity coatings can be sprayed. The airless spraying machine with high pressure can even be used to spray dynamic coatings or coatings containing fibers. The coating viscosity of high-pressure airless spraying machine can be as high as 80 s. Because the coating with high viscosity can be sprayed and the solid content of the coating is high, the coating sprayed at one time is relatively thick, so the spraying times can be reduced.

4. The workpiece with complex shape has good adaptability. Due to the high pressure of the high-pressure airless coating machine, it can enter the tiny pores on the surface of too complex workpiece. In addition, the paint will not be mixed with oil, water, magazines, etc. in the compressed air during spraying, eliminating the paint film defects caused by water, oil, dust, etc. in the compressed air, so that a good paint film can be formed even in the gaps and corners.

Disadvantages:

The diameter of paint mist droplets of high-pressure airless spraying machine is 70~150 μ m. 20~50 for air spraying machine μ m. The quality of paint film is worse than that of air spraying, which is not suitable for decorative coating of thin layer. The range and output of spray can not be adjusted during operation, and the nozzle must be replaced to achieve the purpose of adjustment.

Post time: Dec-02-2022